For the first week’s homework assignment, I decided I wanted to build a switch that could be used in a variety of ways. Although the examples that we examined in class, such as the mustache switch, were creative, they seemed rather limited and required very precise conditions to operate. In addition, I felt that simply modifying previous examples by simply using a different body part to activate the switch seemed unoriginal. This left me with two primary paths to explore for this project.

- Create a switch that is powered something other than human interaction (e.g. wind, heat, water, etc.).

- Create a more general purpose switch which can be powered by a variety of sources.

I ended up choosing the second of these options, as it opened a broader array of possibilities for interaction, and seemed more conducive to creating a reliable device that wasn’t limited to very narrow parameters.

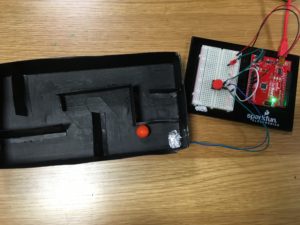

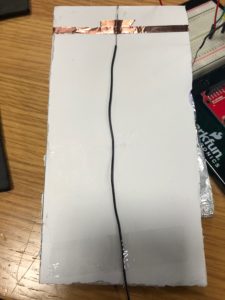

Following this path, I decided to build a pressure sensor, which would activate a light when pressed down upon. To test the idea, I placed two pieces of copper tape, each connected to a wire, on opposite sides of a piece of fabric containing a hole in the middle. When the wires were pressed, the two strips of copper tape would touch, completing a circuit. When they were released, the switch would open, breaking the circuit.

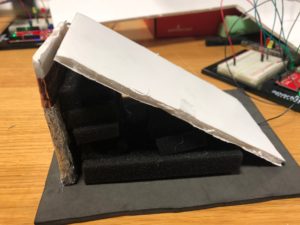

This early version had several issues, however. The fabric had to be pressed together in a specific place to close the circuit, making it difficult to turn on the light by simply placing an object on top of the switch. To solve this, I built a enclosure around the switch using two pieces of wood that I found in the lab, as well as several pieces of foam. When pressed, the foam compressed and the top piece of wood came into contact with the fabric, activating the switch. However, I found it difficult to keep the wires of the circuit connected to the copper tape in the switch.

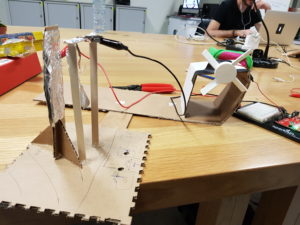

To fix this, I built one final version, using metal buttons to clamp the copper tape, fabric, and wires together. I also replaced the wood enclosure with new laser-cut wood parts, and added shrink wrap to make the wires neater.

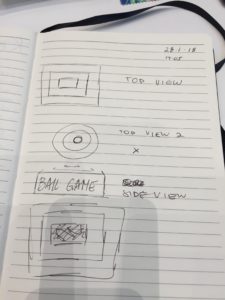

There were a couple of designs that I thought of. One of the ideas consisted of circles but I decided against it because it would logistically be a hassle. Using a square or rectangle would work just as well and without the trouble.

There were a couple of designs that I thought of. One of the ideas consisted of circles but I decided against it because it would logistically be a hassle. Using a square or rectangle would work just as well and without the trouble.

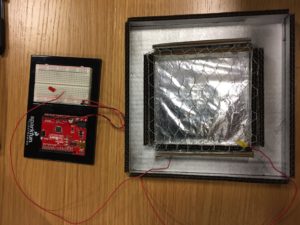

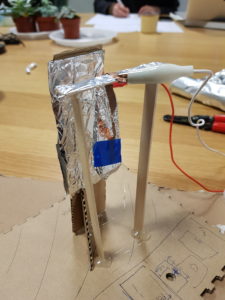

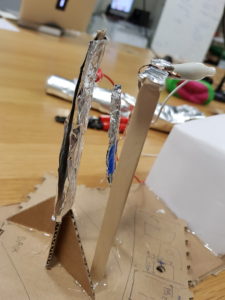

After making sure the LED turns on, I cut and taped some wire to both the aluminum and chicken wire. I put all of the parts together using hot glue.

After making sure the LED turns on, I cut and taped some wire to both the aluminum and chicken wire. I put all of the parts together using hot glue.

You blow on the hanging piece of cardboard wrapped in foil, and it’ll make contact with the stationary piece of cardboard wrapped in foil. In order to not make the hanging piece of cardboard hefty, the current is transferred through copper tape to the top wooden stick, also wrapped in foil, where the alligator clips connects this piece to the rest of the circuit.

You blow on the hanging piece of cardboard wrapped in foil, and it’ll make contact with the stationary piece of cardboard wrapped in foil. In order to not make the hanging piece of cardboard hefty, the current is transferred through copper tape to the top wooden stick, also wrapped in foil, where the alligator clips connects this piece to the rest of the circuit.